Engineering design is an intricate process that involves the application of scientific principles to create solutions that fulfill specific requirements. One of the critical aspects of the design process is the implementation of safety factors, a protective measure intended to counteract uncertainties and variations in material properties, loading conditions, and design predictions. The significance of these safety factors cannot be overstated — they could mean the difference between a design that stands the test of time and one that fails prematurely—. The design of roof systems does not escape this engineering challenge. Selecting the proper roofing systems is of special importance in high wind regions such as Puerto Rico; and it largely has to do with safety factors. We’ll see why.

The Puerto Rico Building Code adopted the ASCE 7 code that includes provisions for wind pressure in the design of roofing systems. Now, with the latest updates to this code there is an interesting discussion regarding safety factors, whether or not to increase wind pressures and whether or not to reduce the strength of roof assemblies; since the irreferences between norms and some ambiguities leave margins for different interpretations. In the following paragraphs, we organize the information in this regard to elucidate and contribute to the construction of engineering criteria on this issue. We delve the role of safety factors in the engineering design of roofing systems, exploring their importance and how they influence the selection of appropriate roofing materials.

Design Philosophies

First of all, in order to understand the factors associated with the design of roofs, let’s review the two design methodologies known and typically present in standards: Allowable Stress Design (ASD) and Load and Resistance Factor Design (LRFD). A summary of fundamental issues of these methods extracted from the Source is presented: https://www.oaxaca.gob.mx/sinfra/wp-content/uploads/sites/14/2016/02/Manual_de_diseno_para_la_construccion_en_acero-AISC-ahmsa.pdf

Allowable Stress Design (ASD)

This design method is the oldest and consists of determining the stresses that occur in the critical sections of a structural member under the action of service loads, considering an elastic behavior of the material. A member is considered to be correctly designed when the stresses caused by the service loads do not exceed the allowable stresses.

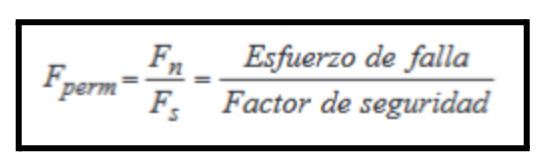

The allowable stresses are calculated according to design specifications according to the type of structural element and stresses to which the structure is subjected. In general, they are obtained by dividing the failure stresses by a factor of safety; Normally, the yield strength or yield stress (Fy) or the minimum tensile rupture stress (Fu) is adopted as the failure stress, depending on the design being carried out. The following box shows the expression that indicates the maximum allowable force as a reason for the failure stress.

The margin of safety is represented by the factor of safety. To get an idea of magnitudes, this factor is usually 1.67 for design of structural members in tension and 2.0 for design of girder-column structural connections.

Load and Resistance Factor Design (LRFD)

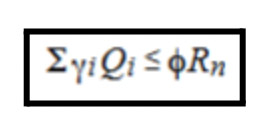

This method was introduced more recently and is currently co-existing with ASD in some standards. It is also known as design by limit states or ultimate resistance and consists of first determining the actions (loads or moments) that occur under the effect of design actions or factored loads. In general, factored loads are obtained by multiplying service loads by a factor greater than unity. These are compared to a derated nominal resistance.

In summary, as illustrated in the following equation, the safety margin is incorporated into the two factors of load and resistance reduction (γ and φ), and is applied to both sides of the basic design equation: actions against resistance.

The way in which factors of safety are introduced into the design is what fundamentally distinguishes one method from another, or in other words, the way in which the relationship between applied loads and capacities is handled.

In the LRFD, what is associated with the variation of the loads is taken separately, with a safety factor on the side of the required resistance, and what is associated with the variations of the material and the construction, through resistance factors on the side of the rated resistance. In the ASD it can be said that the two safety factors are combined into one. If the safety factor is broken down into two independent factors, load and resistance, a more consistent effective factor is obtained, which results, depending on the load, in safer or lighter structures, as in the LRFD.

For example, in structures with highly predictable loads, such as dead load, the variation associated with LRFD factors is lower than in ASD, resulting in a lighter structure. And on the other hand, for structures subjected to highly unpredictable loads, such as live, wind and seismic loads, in the LRFD the ratio is higher than in the ASD, which generates stronger structures. In short, the ASD is conservative for structures with predictable loads and non-conservative for structures with less predictable loads. Source: https://www.bgstructuralengineering.com/BGDesign/BGDesign05.htm

In the design of roof systems, although either method can be used, the ASD approach is still commonly used.

Do the ASCE 7-16 criteria for wind loads include factoring factors? With which design philosophy?

Having understood the operation of the two usual methods, ASD and LRFD, we will discuss the precision of wind resistant component design.

As is known, in Puerto Rico the construction legislature is governed by the Puerto Rico Building Code, and this in turn refers to ASCE 7-16 on the issue of charges. Therefore, let’s start by investigating what these standards pose in the loads associated with the winds.

The wind speeds represented on the maps provided in ASCE 7-16 are maximum design or ultimate wind speeds (associated with the LRFD). These speeds were introduced in the ASCE from the 2010 version, since prior to this, nominal wind speeds (associated with the ASD) were used. This change suggested or suggested more consistency in safety margins for different types of loads and for different methods of structural analysis; However, in the field of ceiling design, the ASD method is still used in most cases today. Then, to obtain the nominal equivalent wind speeds (for use with the Allowable Stress Design, ASD), factors must be applied that decrease these maximum wind speeds established on the maps.

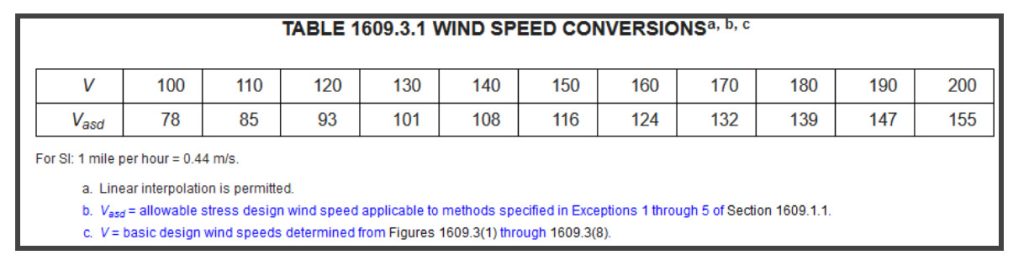

This is where the PRBC 2018 comes in, which although it establishes in section 1609 that wind loads must be determined according to chapters 26 to 31 of ASCE 7, is more precise in the calculation of loads associated with wind, directly stating the relationship VASD=0.6 V, to work on the corresponding approach (ASD), and presents a practical summary table with the results of said relationship shown in Figure 1.

Wind Speed Conversion Table (Source: PRBC 2018)

Source: https://codes.iccsafe.org/content/PRBC2018P1/chapter-16-structural-design#PRBC2018P1_Ch16_Sec1609

With this speed, we proceed to calculate the pressures associated with the components and coatings, with the ASCE formulations that incorporate factors associated with site characteristics (such as topography, elevation, etc.) and building characteristics (such as areas and enclosures). , distinguishing, in the case of ceilings, different pressures for corners, edges and central areas. Although this subject may be broad and beyond the scope of this article, mentioning the calculation route in general terms seems to us to help us understand the objectives and forms of factorization.

On calculating pressure from wind speed

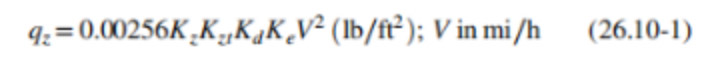

The equation,

established in ASCE 7-16, provides an approximation of the total pressure or force, in pounds per square foot (PSF), as a function of wind speed in miles per hour (mph). The constant 0.00256 is used to convert the units appropriately. This approximation assumes that the pressure on the surface is uniform and does not consider other factors such as the shape of the surface or variations in air density. Therefore, it provides a simplified estimate of the pressure exerted by the wind based only on the speed of the wind. For more accurate and detailed pressure measurements, especially in engineering and architectural applications, additional factors such as surface shape and orientation, wind direction, turbulence, and other environmental conditions must be considered.

Resistance of Roof Systems (FM 4474)

Overcome what concerns the charges, now comes what is related to the resistances.

There are several brands or companies that manufacture or carry out studies of materials and roof systems. The important thing is to have the documentation referred to by the manufacturer or the specifications of the tests carried out in order to have sufficient elements and decide the factors that apply according to the case.

In this writing, we mention the systems endorsed by Factory Mutual, which uses the FM 4474 standard as a procedure to determine the resistance level of roof systems. When reviewing this document, it is evident that the resulting resistance level is the equivalent of nominal resistance; therefore, in the event that LRFD is applied, the corresponding factor must be applied to reduce the nominal resistance, and if ASD is applied, also take the considerations of the case.

It is worth noting that if working with another type of roof system, other than those validated through Factory Mutual standards, it must be confirmed whether the prescribed resistance is nominal resistance or design resistance, that is, it already incorporates factors of reduction.

In any case, as a result of this discussion, the importance of knowing the way in which the loads that act and the resistances of materials, structures or bearing systems are obtained is highlighted, in order to maintain consistency in the design, whatever the philosophy that applies.

| The wind load derived from the standard maps contain factors of majority. Therefore, if the ASD is going to be applied, the speed of the map must be reduced as indicated by the PRBC to continue with the calculation of wind pressures; and divide the resistance of the roof systems by two; Thus, coherent factorization is applied to this design philosophy. |